Please click below to sign in to your MyToyota account

Forklift Battery Maintenance & Handling Best Practices

The proper maintenance and handling of forklift batteries is imperative to their longevity. There’s a right way and a wrong way to maintain and handle forklift batteries and doing it properly will ensure your investment is maximized.

Proper Handling

Forklift batteries can be heavy and dangerous if not handled properly, so it’s important to be educated on the correct way to handle them. Use these tips for some ideas about handling batteries properly:

- Use special equipment, like a walkie pallet jack equipped with a transfer carriage, to maneuver the battery. Because of the weight of some forklift batteries, no single person should attempt to move a forklift battery alone. Steel toe shoes should also be worn while moving the batteries.

- An eye and hand washing station should be nearby. Should any hazardous liquid come in contact with hands or eyes, a hand and eye washing station should be conveniently located nearby to remove it as quickly as possible.

- Chemical-resistant protective gear should be worn while maneuvering batteries. Having a conveniently located eye and hand washing station is necessary, but chemical-resistant gear should also be worn to keep the need for the station at bay. This includes safety glasses and gloves.

- Remove all metallic jewelry when handling and charging.

Proper Charging

Properly charging a battery is all about doing it at the right time, for the right amount of time. Use these tips when charging your forklift battery:

- Designate an area specifically for battery charging. This is an OSHA-recommended best practice.

- Remember that lead acid batteries should be charged at 80 percent depth of discharge. Charging prior to 80 percent can result in reduced battery life depending on the type of battery. Discharging the battery past 80 percent depth of discharge can also be detrimental.

- If your battery overflows, take time to rinse it. Rinsing your battery after an overflow will help prevent corrosion.

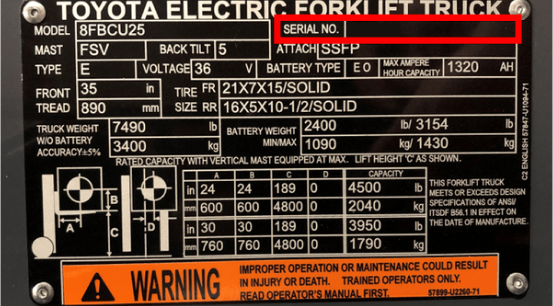

- Ensure compatibility between the battery and the charger. The charger that is being used should match the voltage/amperage of the battery. Color coding the connectors and clearly labeling the chargers can help to prevent accidentally connecting a battery to the wrong charger. Proper training is also imperative.

- Avoid overcharging the battery. Some batteries have battery management systems that can prevent overcharging. If yours doesn’t, take precautions not to overcharge it, which can reduce the battery’s life.

- Charge and operate the batteries at the proper temperature. Charging a battery in extreme cold or heat can cause reduced service life. Since battery types and specifications may vary, contact the battery manufacturer for their recommended charging temperature range.

- Add water when needed after the charging cycle. Adding water to a wet-cell battery prior to charging the battery is a common mistake. Pure or distilled water should be used and the watering should occur after a full charge cycle to bring the electrolytes to the proper level.

- Ensure the charger is turned off before connecting or disconnecting the battery.

Request A Quote or for pricing, parts & more, click here to find a dealer near you.