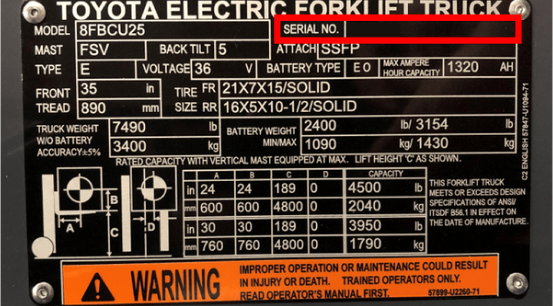

How to Find Your Equipment Model Number.

Finding the right parts for your equipment is easy when you have your model and serial number which can be found on the data plate. Luckily, a forklift data plate is installed on every truck on the market to help you understand what your forklift can do and provide vital information.

Model Number: The model number of your toyota forklift is extremely important for relaying information to your dealers about repair or technical assistance and for looking up replacements part!

Serial Number: The serial number on your lift is the most important number.The model serial number combination will allow us to provide you with the parts that will fit your particular piece of equipment.

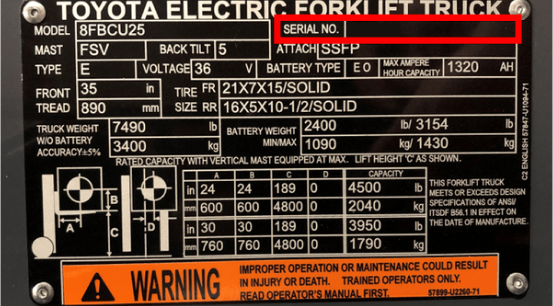

How to Find Your Equipment Serial Number

Finding the right parts for your equipment is easy when you have your model and serial number which can be found on the data plate. Luckily, a forklift data plate is installed on every truck on the market to help you understand what your forklift can do and provide vital information.

Model Number: The model number of your toyota forklift is extremely important for relaying information to your dealers about repair or technical assistance and for looking up replacements part!

Serial Number: The serial number on your lift is the most important number.The model serial number combination will allow us to provide you with the parts that will fit your particular piece of equipment.

Need some help? For further assistance or more information, contact your local Toyota Dealer.

Please click below to sign in to your MyToyota account

Don't have an account?

What is the Value of a Warehouse Management System?

In today’s world of supply chain, a warehouse management system (WMS) is vital to a company’s operation. A WMS is software used to manage the processes of a warehouse, primarily inventory, picking, shipping, and auditing. From the time a product is pulled off the trailer to the time it leaves the warehouse, a WMS streamlines the operational processes the products go through during its time in the warehouse. This leads to automated processes and better inventory management, while minimizing cost and lead times and enhancing the safety of warehouse employees. A WMS presents tremendous value for a warehouse, but these values are game changers for your operation.

Minimizing Costs While Enhancing Safety

A good WMS can help you enhance safety while reducing operational costs in running your warehouse. For example, a WMS can help you develop and manage the routes used by warehouse workers and forklift operators for picking and putting away products. This allows to you to create safer and more efficient routes for use by your warehouse employees in picking and putting away products.

Data

The real-time data collected by a WMS during operation can help you make operational decisions. Through the data collected, you have visibility into high volume products and slow-moving products. Having this window allows you to make decisions to balance your inventory so you aren’t carrying too much or too little stock. This can also help you understand where those products should be located in relation to your shipping and receiving locations to enhance warehouse safety and productivity.

Transparency

With access to real-time data, the warehouse can reduce lead-times; create operational efficiencies, and lower costs with a WMS. The data collected, including on-hand inventory, turn rate, orders, shipments, among other metrics; customer service can better respond customer questions and inquiries. The transparency into the data can help improve customer relationships and satisfaction.

Kaizen

In the end, the value of a WMS is continuously improving your warehouse operations. Kaizen, or continuous improvement, is a vital part of Toyota Production System and is the concept that incremental improvements can be made every day. From process improvements to using the data to being proactive, the ultimate goal is to leverage the WMS for Kaizen, or continuous improvement.