Please click below to sign in to your MyToyota account

Butternut Mountain Farm Customer Story

Sweet Success

Butternut Mountain Farm keeps maple syrup flowing with the help of Toyota forklifts.

Most people would be surprised to learn that it takes about 40 gallons of sap from a maple tree to produce a single gallon of syrup. The folks at Butternut Mountain Farm are well aware of this, as they are one of Vermont’s leading processors and distributors of pure maple syrup and maple-related products, such as cookies, candies, and granulated maple sugar used as an ingredient in other foods.

The family-owned company produces its own branded syrup and many private-label brands for mass merchandisers, retailers, natural food companies, and others that crave the unique and naturally sweet taste of maple. Butternut Mountain Farm has its own 1,000-plus acre farm to draw sap from about 17,000 tree taps, but it relies on regional farmers to supply it with the majority of the maple syrup that it packages. The farmers take the sap and boil it down to raw syrup before sending it in large drums to the processing facility in Morrisville, Vt. Once there, the syrup is filtered, packaged, warehoused, and then distributed. The building can hold up to 8 million pounds of syrup.

Bulk Syrup Handling

Butternut Mountain Farm trusts a fleet of Toyota forklifts and warehouse equipment to move loads throughout its facility. These include the heavy stainless steel drums of raw syrup, large totes that can hold 350 gallons, and finished goods from packaging.

“The forklifts help us store and stack,” says John Kingston, CEO. “They are critical for our storage management and safety.”

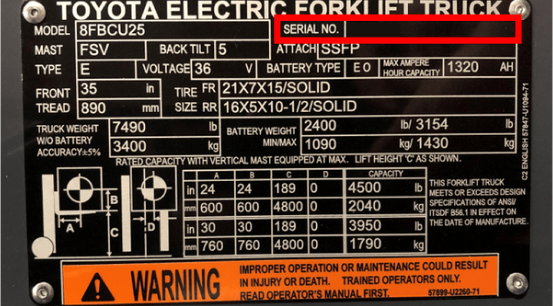

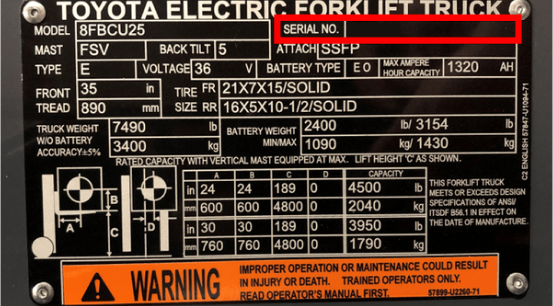

Two reach trucks are employed within the production storage area to stack the drums of raw syrup before processing. These forklifts have “parrot beak” attachments that can lift two drums at a time, side by side, by grabbing the rims of the drums and supporting the drums’ backs. The drums are then floor-stacked five levels high, with drums placed directly on top of one another. These Toyota reach trucks are rated for a normal capacity of 4,500 pounds. When fully extended with the attachment, they can lift 1,500 pounds, which is plenty of muscle to raise the drums easily onto the tops of the stacks.

When the drums are needed in production, these forklift trucks also take them to the filling machines. The syrup is batched, filtered, and heated.The sweet liquid is then poured into jugs and bottles of various sizes – everything from large containers sold in club stores to single-serve bottles used in restaurants.

The individual farmers own the drums, so they must be washed and returned to them.

“It is critical that we take good care of the drums and return them in good condition,” says David Ellis, purchasing and supply chain manager. “The careful handling with the Toyota forklifts minimizes damage.”

Finished Goods

In addition to the reach trucks, four 3,500-pound capacity sit-down forklifts work primarily in the warehouse. These bring finished goods from production to storage in pallet racks. These 3-wheeled electric vehicles offer tight turning radiuses for negotiating the aisles, and they are especially well suited for the 90-degree turns into the facility’s drive-in rack locations.

Additionally, two walkie-stacker trucks, three electric pallet jacks, and several manual pallet jacks keep products moving throughout the building and in and out of delivery trucks. Keeping that fleet in top operating condition is the job of the local dealer, Northern Toyotalift, based in nearby Burlington. The company serves Toyota Industrial Truck customers throughout Vermont, New England, and Upstate New York.

“The customer service that we get from Northern Toyotalift is absolutely excellent,” says Rob Shatney, warehouse manager. “Toyota just seems to have a really solid product that has always served us well. They are reliable. They don’t break down often, and if we do have an issue, it is taken care of right away. So, really we see it not only as our best option, but really our only option.”

Download a PDF of this story from DC Velocity HERE.